- EN 441 stainless steel flat bar Hot rolled / cold drawn

- STS304L stainless steel round bar

- Stainless Steel Hot Rolled Flat Bar

- ISO Stainless Steel Angle Bar

- straight cut stainless steel wire sus304

- 304 bright soft annealed stainless steel wire

- 304L bright soft annealed stainless steel wire

- Stainless Steel Wire

- AISI316 stainless steel round pipe/tube

- 300 Series grade stainless steel round pipe

- AISI/SUS stainless steel pipe/tube cold drawn

- ASTM A249 stainless steel round pipe

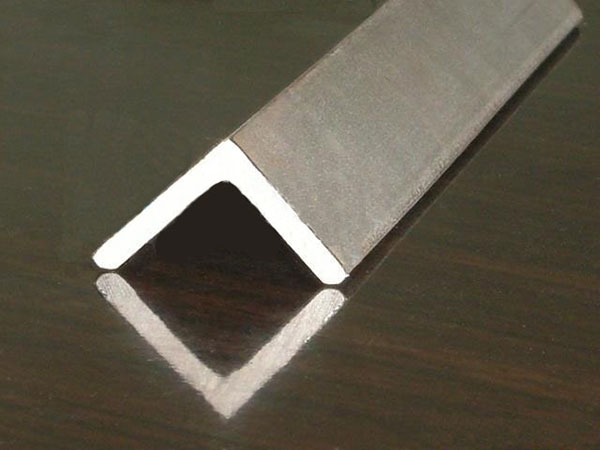

Stainless Steel Angle Bar

Inquiries : 0 - 2014/2/23 19:14:09

Stainless Steel Angle Bar

Grade: 201, 202, 303, 304, 304L, 316, 316L, 321, 430, 410, 420, etc.

Standard: ASTM, A276, EN10272, GB9787.

Top Right angle Tolerance is 90。 ±35。.

Tolerance of Cut - length or Multiple Length: 0~50mm.

Max bending: 4mm.

Max bending ≤ 0.4% length/pcs (angle size above 5#)

According to the negotiation by two sides, supplier can provide angle whose max bending ≤ 0.4% length/pcs.

Equilateral Angle Steel mustn't have obvious twist.

Brief Introduction and Mechanical Property of Stainless Steel Hot - Rolled Equilateral Angle Bar.

Stainless Steel Hot - Rolled Equilateral Angle Bar (GB/T 4227).

Specified length is 4、5、6 m. Length Tolerance ≤ +40m/pcs.

Shape: Right angle Tolerance is 91。 ±2。.

Max Bending: 4mm/m. Whole body's Max bending ≤ 0.4%length/pcs.

Condition of Delivery: Austenite in Solution, Ferrite in Anneal or in accordance with client's detailed requirement.

Surface: Pickled or Sand blasting. No harmful imperction exist.

Usage: Bars,Public facilities,construction and etc.

2.Chemical composition of 304 stainless steel plate :

C | Mn | P | S | Si | Cr | Ni | Mo | N | Cu. |

0.07 | 1.78 | 0.039 | 0.01 | 0.75 | 18.3-18.9 | 8.0~8.7 | -- | -- | -- |

3. About Packing

A. wood packing

B.Woven bag packaging

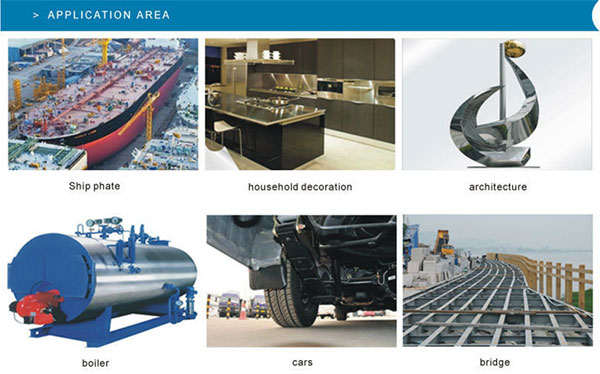

Product Usage

Stainless Steel Bar (Round Bar, Hexagon Bar, Square Bar) Widely Used in the areas such as Stainless Steel Fasteners, Chains,Kitchen and Sanitary wares, Furniture handles, Handrails, Electroplating and Electrolyzing pendants, Foods, Electron, Petroleum,Construction and Decoration, etc. Products have a high strength after cold- working. Electronic products parts, Medical appliances, Springs, Bus Inside and Outside packaging and building, Street Lamp Posts, etc. Decoration materials and Outdoor Publicity Billboard. Used for the products which have the Anti- Stress Corrosion requirement. Electron Products, Table-wares, Bolts, Nuts, Screen Mesh, Burner and so on.