- EN 441 stainless steel flat bar Hot rolled / cold drawn

- STS304L stainless steel round bar

- Stainless Steel Hot Rolled Flat Bar

- ISO Stainless Steel Angle Bar

- straight cut stainless steel wire sus304

- 304 bright soft annealed stainless steel wire

- 304L bright soft annealed stainless steel wire

- Stainless Steel Wire

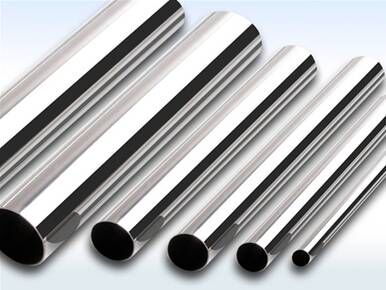

- AISI316 stainless steel round pipe/tube

- 300 Series grade stainless steel round pipe

- AISI/SUS stainless steel pipe/tube cold drawn

- ASTM A249 stainless steel round pipe

ASTM A312 TP316L Stainless Steel Seamless Pipes Specification

Inquiries : 0 - 2015/9/23 10:47:39

Type 316L Stainless Steel is the lowcarbon version of 316 stainless. With the addition of molybdenum, the steel ispopular for use in severe corrosion environments due to the materials immunityfrom boundary carbide precipitation (sensitisation). The material is widelyused in heavy gauge welded components and weld annealing is only required wherethe material is for use in high stress environments. 316L has an extensivevariety of uses especially in marine applications due to the materials highcorrosion resistance.

Benefits of using Type 316L Stainless Steel seamless pipes

Low carbon content eliminates carbonprecipitation in the welding process.Can be used in severe corrosiveenvironments.Improved anti-corrosion scope due to addedMolybdenum.Weld annealing only required in high stressapplications.Very similar to Grade 316 in chemicalcomposition and mechanical properties.316 & 316L steel plate and pipes havecommon properties and are often stocked with Dual Certification, where it isdetermined that both have properties and composition which comply with bothsteel types.

Type 316H is excluded from this scenario by virtue of the fact that unlike 316& 316L, 316H is engineered to work in elevated working temperatures.

Product Range

Specifications: ASTM A/ASME SA213/A249/A269/A312/A358 CL. I to V ASTMA789/A790

Sizes (Seamless): 1/2" NB - 24" NB

Sizes (ERW): 1/2" NB - 24" NB

Sizes (EFW): 6" NB - 100" NB

Wall Thickness available:

Schedule 5S - Schedule XXS (heavier on request)

Other Materials Testing:

NACE MR0175, H2 SERVICE, OXYGEN SERVICE, CRYO SERVICE, etc.

Dimensions:

All Pipes is manufactured and inspected/tested to the relevant standardsincluding ASTM, ASME and API etc.

Background of 316L Stainless Steel Pipes and Tubes

Grade 316 is the standard molybdenum-bearing grade, second in importance to 304amongst the austenitic stainless steels. The molybdenum gives 316 betteroverall corrosion resistant properties than Grade 304, particularly higherresistance to pitting and crevice corrosion in chloride environments. It hasexcellent forming and welding characteristics. It is readily brake or rollformed into a variety of parts for applications in the industrial,architectural, and transportation fields. Grade 316 also has outstandingwelding characteristics. Post-weld annealing is not required when welding thinsections.

Grade 316L, the low carbon version of 316 and is immune from sensitisation(grain boundary carbide precipitation). Thus it is extensively used in heavygauge welded components (over about 6mm). Grade 316H, with its higher carboncontent has application at elevated temperatures, as does stabilised grade316Ti.

The austenitic structure also gives these grades excellent toughness, even downto cryogenic temperatures.